Perfect-Bond Concrete Overlay MethodSurface treatment using water-ND Waterjet System

Method overview

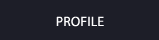

An ultrahigh pressure waterjet at a high flow rate is used to expose aggregate particles in existing concrete to form a rough surface with 10- to 20-mm irregularities. The exposed surfaces are further treated with shotblasting using steel particles cut to special shapes to achieve fine irregularity. This boosts the interlocking strength and bond area between old and new concrete, increases bond strength and completely unifies the layers. This result is a concrete overlay utilizing the strength of existing pavement and having no risk of delamination.

The Nippon Road Co., Ltd. developed the ND Waterjet System for surface treatment, a key element of the Perfect-Bond Concrete Overlay Method.

Concrete overlay with no risk of delamination

Possible delamination of concrete overlay.

Bonding of old and new concrete

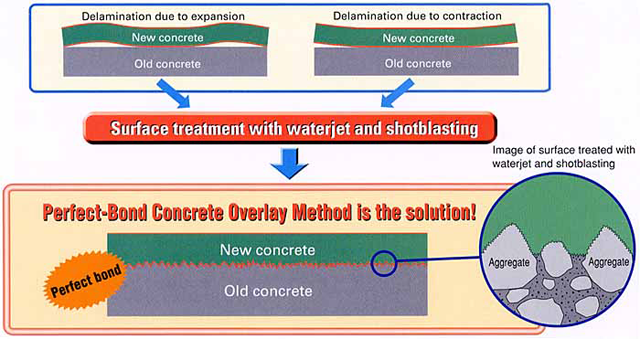

Comparison of bond strengths by representative surface treatment methods

The conditions of treated surfaces of old concrete strongly affect the bond strength with new concrete. The bond strengths obtained by representative treatment methods are as shown in the figure.

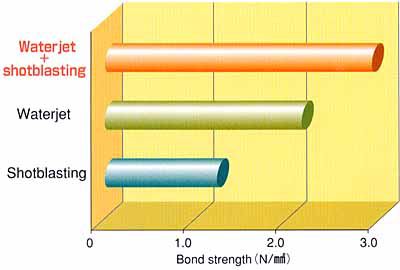

Proof of concrete bond

The figure below shows typical bond strength obtained by the Perfect-Bond Concrete Overlay Method. The strength values are equivalent to tensile strength of concrete specimens without joints. The concrete layers are therefore judged as perfectly unified. These values also satisfy the interfacial bond strength specified by this method (not less than 85% of 28-day tensile strength).

CONSTRUCTION TECHNOLOGY

A

- Ameni-Phalt S series

- Low noise / Drainage Pavement

- Asphalt Mastic

- Underground Water Retaining Wall

- Asphalt Revetment

- Pavement of Dike Sloping

- Automobile Proving Grounds/Bicycle Race Courses

- Pavement of Straight and Curving Slopes-Lateral paving method

D

- Deep Stabilization

- Improvement of Weak Sub-grade

F

- Foamed Mastic Seal(FMS)

- Hot-mix Surface Treatment

- Foamed Stabilization

- Mixed- On-Site Stabilization with Straight Asphalt

H

- Hard Guss Asphalt

- Guss Asphalt Pavement

- HIGH SPEED TRACK

- BANK PAVING SYSTEM

I

- Interlocking Block Pavement

- Irregular-shaped Pavement

M

- Mini Road

- Instant Paving Material

N

- ND-IT Construction System

- ICT (Information Communication Technology) Construction System

O

- Omnicourt

- Loose Lay Installation/Sand Fill System

P

- Perfect-Bond Concrete Overlay Method

- Surface treatment using water-ND Waterjet System

- Permeable Color Pavement

- Hot-mix Pavement

- Poliment-Ultrapave

- Pavement Resistant to Heat and Very Heavy Load of Multi-wheeled vehicles

R

- Rainbow Brick

- Varied Shape Color Tile Method

- Rainbow Color Pavement

- Kao Mat SK

- Rainbow Color Pavement

- Rainbow Color A

- Rainbow Color Pavement

- Rainbow Color E

- Rainbow Color Pavement

- Rainbow Color MH

- R.C.C.P.

- Roller Compacted Concrete Pavement

- Recycle Stabilization

- On-Site Recycling of Existing Pavement

- Recycled Surface

- On-Site Surface of Asphalt Pavement

- Refresh Seal Mix

- Hot Asphalt Surface Treatment Method

- Refresh Seal Mix-H

- Hot Asphalt Surface Treatment Method (Hard Type)

- Road Planing

- Cold Planing

- Road Stabilization

- Improvement of Base Course and Sub-grade

- Rolled Asphalt

- Pavement Resistant to Abrasion and Skidding

S

- Safety Grooving

- Grooving for Skid-resistance

- Semi Hot Pave

- Warm Mix Asphalt

- SKID-PANEL

- Pre-cast Low μ Road

- Soft Step A

- Acrylic Resin Type

- Soft Step Grainr

- Urethane Rubber Chip N and R Type

- Soft Step Grainr

- Urethane Rubber Chip P Type

- Soft Step Master

- Urethane Solid Type

- Soft Step Pro

- Soft Acrylic Resin Type

- SPRINKLING NOZZLE

- Sprinkling Nozzle for Proving Ground

- Steel-Fiber-Reinforced Concrete(SFRC)

- Steel-Fiber-Reinforced Concrete Pavement

- Stone Mastic Asphalt

- Abrasion-and-Flow Resistant Pavement